plastic recycling

Plastic recycling (in English: Plastic recycling) is the process of recovering plastic waste and reprocessing them into useful products.[1]

Plastic recycling is described as the process of recovering waste or plastic waste and reprocessing the material into useful products, sometimes in a completely different form than the original state. Classification based on the final product Any given recycling process can be divided into three methods: primary recycling, secondary recycling, and tertiary recycling. where plastic is reused to meet energy needs instead of being converted into chemicals or fuel. There are several technologies for recycling such as: resin, mixed plastics and compatibilization of plastic resins. There are many uses for recycled plastics. The reuse of recycled plastics has become significant in many industries, from reuse in the same primary use, to use in low-demand applications and advanced recycling industries. However, recycled products are more commercially competitive.

What are the most common recycled plastics?

- PET: (polyethylene terephthalate) is a popular thermoplastic, commonly used in plastic bottles.

- PVC: (Polyvinyl Chloride) is another thermoplastic material, it is one of the most widely used items, which is usually used in wires, pipes, and bottles.

- HDEP: (High Density Polyethylene) is also a thermoplastic. which is used in the production of gallons and pipes.

- LDPE: (low density polyethylene) which is the opposite of HDPE. This type cannot be easily recycled due to its low density and high cost, and it is better not to worry about recycling this item.

- PS: It is a polymer. Examples of products made from this plastic include plastic cutlery and disposable containers.

- PP: is also a polymer. Manufacturers often use it to make plastic boxes, plastic furniture and plastic glass lids. In most cases, recycling companies reject it for recycling.

Plastic recycling methods

- Traditional method: melting plastic waste and turning them into new products through a process called injection molding.

- Advanced recycling: Advanced plastic recycling is a process through which chemicals break down plastic materials, which we will examine further.

Step by step process of plastic recycling

- Step 1: Collecting plastic waste: The first step to recovering plastic is collecting plastic waste.

- Step 2: Classification of plastics into specific categories: The second step is to classify plastics based on color, use and size.

- Step 3: Wash to remove impurities

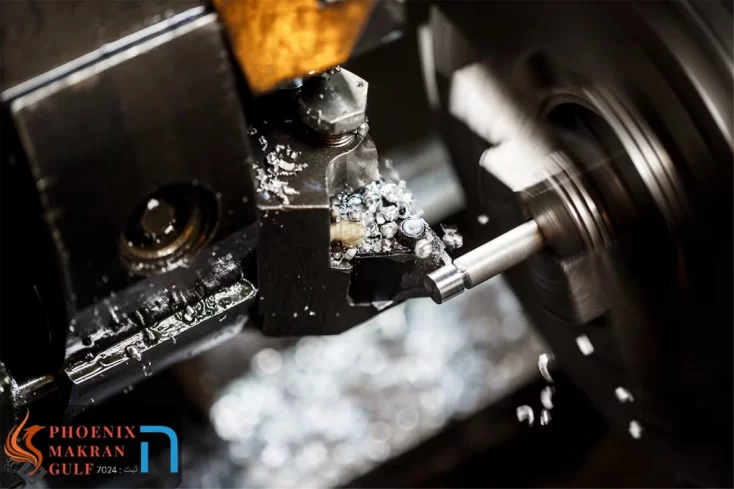

- Step 4: Shredding and resizing: This process is done immediately after washing the plastic. It is impossible to recycle plastic under normal conditions. There is a need to resize plastic materials in a form that can be recycled. In this fourth process, the material is put into shredders to convert the plastic into the desired parts.

- Step 5: Identification and separation of plastics, which can also be done in the plastic shredding stage.

- Step 6: Blending: Blending is the last process in plastic recycling. This step is where recyclers turn the plastic particles into materials that manufacturers can recycle. Compounding involves crushing and melting plastic particles to create pellets. This process is also called extrusion.

Phoenix Makran Gulf Company, manufacturer of shredders, for information and orders, refer to the link below.