Turning, a term that resonates throughout industry, is a technique that paved the way for modern machining and has become a cornerstone of mechanical engineering.

This article from Makran Phoenix Gulf examines the explanations and tips related to turning and explains the parameters, types of models, types of related equipment and applications.

What is turning?

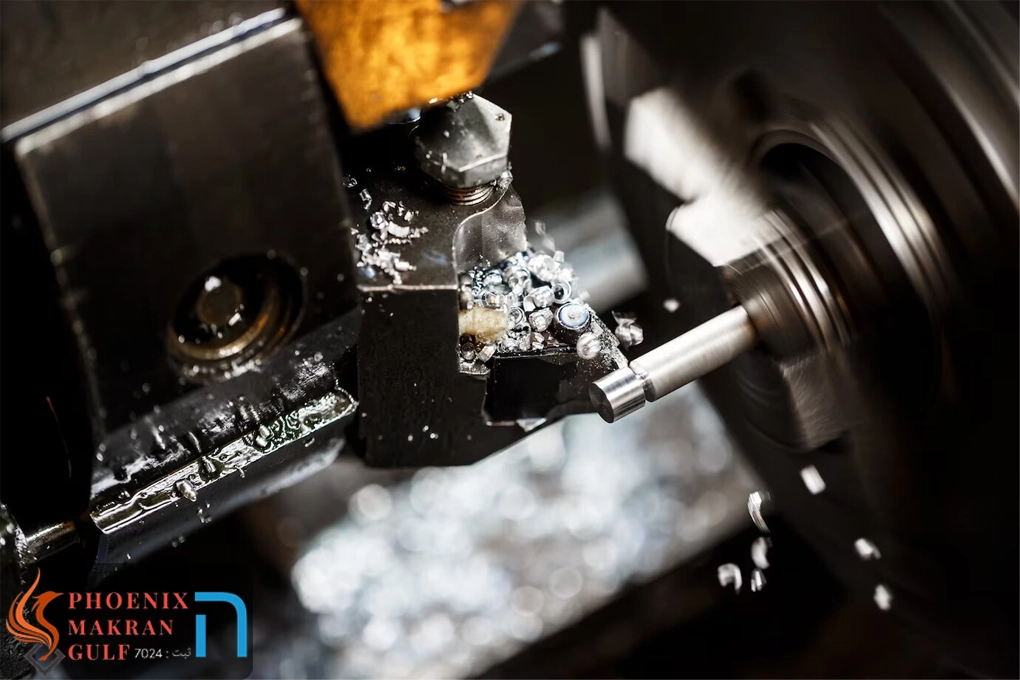

Turning is a type of machining operation that involves a cutting tool, this tool shapes the desired material while rotating around an axis. With turning, operators have good access to different designs and ideas and can produce parts with high tolerance. It is a process that allows the creation of internal and external surfaces, even contour surfaces, with unparalleled precision.

Manufacturing companies use a variety of machining processes to shape and shape metal parts. One of them is turning. Not to be confused with milling, turning is a machining process that involves the use of a stationary cutting tool to remove material from a rotating workpiece. As the cutting tool presses against the workpiece, it removes material, thereby changing the size and shape of the workpiece.

Related article: What is an industrial inverter or drive and what is its application?

Turning process

There are various metal turning processes, each of which has specific applications. Their key aspect is that they all rely on the same turning principles, but are more specialized for use on metals. The basic principle involves high-speed rotation of the metal workpiece and a cutting tool to make cuts along several axes. This process often relies on a lathe specifically designed for metalworking.

Metal and steel turning generally refers to a set of processes such as drilling, forming, stabbing, and grooving, all of which rely on the same principle and are often performed as part of a single process. One of the main strengths of metal turning operations is the production of geometric and circular shapes. Although metal turning techniques can create several complex geometries. This process is now suitable for applying a wide range of metals including ferrous metals such as cast iron and steel, copper and nickel alloys, aluminum, etc.

In short, a cutting tool is applied against a rigid piece of material to remove material and create finished parts. Today, CNC (Computer Numerical Control) is also used for automatic turning.

What are the main principles of turning?

Turning is based on a simple but completely efficient principle:

- The workpiece is rotated at high speed while a single-point cutting tool passes along the surface of the workpiece, removing a thin layer of material.

- The cutting action is performed at the point where the cutting edge of the tool meets the workpiece.

- This cutting speed, along with the feed rate (the speed at which the cutting tool moves relative to the workpiece), determines the shape and surface finish of the final product.

Related articles:

What is an industrial gearbox? | Types and application in industry

What is shaft coupling? Types and applications

What products are made by turning?

Turning produces rotationally, usually axisymmetric, parts with many features, such as holes, grooves, threads, tapers, steps of various diameters, and even curved surfaces.

Products that are completely machined often include components that are used in limited quantities, such as custom-designed shafts and fasteners.

It is also often used as a secondary process to add or modify features on parts made using a different method.

In manufacturing, metal turning is used to make custom parts for machinery such as shredder machine parts or to shape materials for customized components.

What metals are used in metal turning?

- Carbon steel

- copper

- stainless steel

- aluminium

- Zinc

- magnesium

- Lead

- nickel

- Tin

- Titanium

What are the advantages of turning process?

The advantages of the turning process are as follows:

– All materials can be cut

While turning is mainly used for machining metals, any material can be used in turning, including wood and plastic. This makes turning a very flexible process.

– high resistance

Because of the strength and high level finishes that turning can provide, this technique can be used to create very high tolerance parts.

– High speed

The rotation of the lathe has a short duration. Because turning is a fast process, preparation time is short.

– No need for a highly skilled operator

Turning does not require a highly skilled operator. To operate a CNC lathe, a machinist can complete a series of training courses and receive certification from a recognized industry training organization.

– The material removal speed is adjustable

Another advantage of turning lathes is that the speed of material removal can be adjusted. Lathe machines can remove material at different speeds depending on the machined material or the desired final product.

– Reducing energy consumption

It requires less energy and power than other processes.

Types of operations in the turning process

- Turning

- Facing

- Grooving

- Cut-off

- Parting

- Threading

- Drilling

- Boring

- Reaming

- Tapping

See also: Metal scrap recycling line

What are the applications of turning in industry?

- Manufacturing of industrial machinery

- Auto Parts

- Airplane crashes

- Manufacture of aerospace steel parts

- Prototypes for some products

- Some electronics

- Telecommunications

Conclusion

Turning is an inseparable part of the industry. This technique is used to cut and shape materials, remove excess parts and create finished parts. By turning parts with tools, it is possible to create a variety of geometric and engineered shapes, grooves, threads, tapers and even curved surfaces. Currently, modern methods such as CNC machines are also used.

Phoenix Makran Gulf Company, designs a variety of smelting and recycling products, including the complete launch of the iron waste recycling line, for more information and order, refer to the link below

It’s appropriate time to make some plans for the future and it is time to be happy.

I have read this put up and if I could I wish to

counsel you some interesting things or suggestions.

Perhaps you could write next articles relating to this article.

I wish to learn more things approximately it!