Iron scrap recycling

Scrap iron recycling is a growing industry. Maintaining a sustainable future is critical, and we can do this by reducing our carbon footprint in the manufacturing and construction industries. Iron scrap recycling and iron scrap recycling line is a cost-effective and effective way that can contribute to a more environmentally friendly future.

Metals are extremely valuable materials, which can be recycled over and over again without losing their properties. This means that scrap metal has a high value, which encourages people to collect it to sell to recycling businesses.

But there is more to it than financial motivation. There is also an environmental imperative. Metal recycling helps us conserve natural resources while requiring less energy for processing than producing new products using virgin raw materials.

Metal is a valuable and common commodity, but it is often very heavy and bulky, especially scrap metal. Scrap metals can be recycled many times without changing their properties. According to the American Iron and Steel Institute (AISI), steel and aluminum are the most recycled materials on the planet. Other common recycled metals include copper, silver, brass, and gold.

Phoenix Makran Gulf Company, is the designer of all kinds of smelting and recycling products in different types and dimensions, for more information and order, refer to the link below.

Iron scrap recycling line

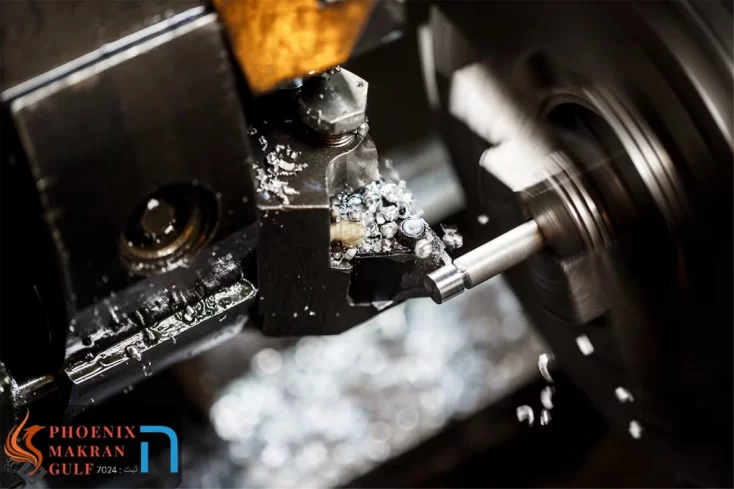

metal scrap recycling line is a cleverly developed initiative. Used car body and scrap metals (such as scrap iron, aluminum and engine body, etc.) are shredded by the shredder machine, then they are ready to be melted down and purified for reuse.

Iron waste recycling line is designed for recycling ferrous and non-ferrous metals. which should be affordable, safe and durable with intelligent design. The iron scrap recycling line uses a special metal shredder (shredder) designed for primary crushing and usually a heavy duty hammer mill crusher for further processing. After that, a dust collector system is used to remove dust, a powerful magnetic separator to separate ferrous metal, and an effective separator to remove non-ferrous steel. In all stages, using a conveyor belt, communication between devices and moving waste is done.

A standard line for separation, recycling, processing and sorting of scrap metal crushing should include double shaft crusher, metal hammer crusher, transfer equipment, separation equipment and dust removal system. In some recycling lines, to reduce costs from the crusher No hammer or other items are used.

Use cases of iron waste recycling line

- Crushing, processing and recycling of metal waste

- Car shell and car engine recycling

- Aluminum casting and profiles

- Separation of metals from electronic waste

- Recycling waste of household appliances, etc

- Separation of precious metals

After processing, the recycled material is suitable for direct transport and is usually ready for the melting and furnace stage.

Metal waste recycling process steps

1- Waste collection

The first step in metal scrap recycling is to collect items that contain metals. Scrap iron can be found almost anywhere. including construction sites, industrial facilities, warehouses, landfills, repair shops, etc.

Related articles:

What is shaft coupling? Types and applications

2-Separation and classification of waste

The collected waste is then sorted according to the type of material in a metal recycling center and packaged for transportation. This is done by shredding with a shredder, cutting and compressing.

3-Smelting iron waste

After separation and shredding, metal scraps are melted and purified by steel mills or industrial smelting furnaces. This is done to remove any impurities from the waste.

4- Shaping

Melted and purified metals are now shaped and stored in the form of molds or ingots intended for use in future productions.

5- Use in the production industry

The new metal is now ready to order. It can be sold to manufacturers, where it can be turned into new products or remelted and reused.

Related articles:

What is an industrial gearbox? | Types and applications in industry

Features of a standard railway scrap recycling

- Optimum, intelligent and specialized shredding of iron or metal waste

- Easy-to-control automatic control system such as Siemens PLCs and automatic intelligent control system

- Guaranteed durability and strength for long-term use

- Responsive and expert support

- Reducing energy consumption and that electricity reduces operating costs

- High capacity and high accuracy in sorting, separating and providing quality output capacity

- Long life cutters or blades

- Easy maintenance and low maintenance cost

- The hydraulic motor improves the torque and more stability of the crushing

Phoenix Makran Gulf Company, designs a variety of smelting and recycling products, including the complete launch of the iron waste recycling line, for more information and order, refer to the link below