How to produce and uses wood chips

Many companies often expand their production by purchasing wood shredders, wood chip screeners, and wood chip packers in order to produce the best quality and variety of wood chip products. In this article, you will learn the most valuable wood chip products you can sell and what equipment is needed to produce them.

Wood chips are made from cutting and shredding pieces of wood such as wood residues, roots, logs, branches and wood scraps. These are used as raw materials for the production of wood pulp. Wood chips are organic mulches that are widely used in horticulture, landscaping, and bioreactors for DE nitrification and as a substrate for mushroom cultivation. Reducing and preventing soil erosion, water conservation, supporting the growth of natural seeds, maintaining soil moisture, improving soil fertility and health are some of the key benefits associated with wood chips.

Wood chipping process

For some, it’s just ordinary wood waste from sawing wood, while for others it’s a valuable product made from shredding certain trees, barked and debarked, branches, stumps, roots and other wood waste. will be

The process of making wood chips is called chopping. Any type of wood and its parts can be chopped, but for its successful sale, you must look at the needs of the market and the relevant buyers. There are different types of wood chips, such as residual wood chips (from reclaimed wood, untreated and chipped wood residues), forest wood chips (from forest areas), residual sawdust (from sawing wood) and short-rotation forest chips. (from energy products).

Increasing use of wood chips in industrial applications

Home heating is one of the prominent applications of wood chips. The growth of wood chips in industrial and commercial energy production is expected to drive the market growth. Moreover, the use of wood chips as raw material for the production of wood pulp is expected to drive the growth of the market in the coming period. Increasing demand for wood chips as compost material is another application that is driving the growth of the market.

Use of wood chips and products

It is mainly used as a solid fuel and as a raw material in the wood pulp production process.

The most common use associated with wood chips is horticultural mulch for landscaping. However, it can be reprocessed into playground surface materials or impact attenuation surfaces as a very effective method of reducing fall impact. It is also used in bioreactors for denitrification, restoration ecology, and as a substrate for mushroom cultivation, and even in smoking meat to obtain different flavors.

Wood chips are multi-purpose and have many uses.

Here are the best uses for wood chips from a wood chipper:

- Mulch for landscaping

- composting

- Covering mud

- Grilling and smoking foods

- Create paths

- animal litter

- Playground cushion

- starting a fire

- Erosion control

- Construction of raised beds

- mushroom planting

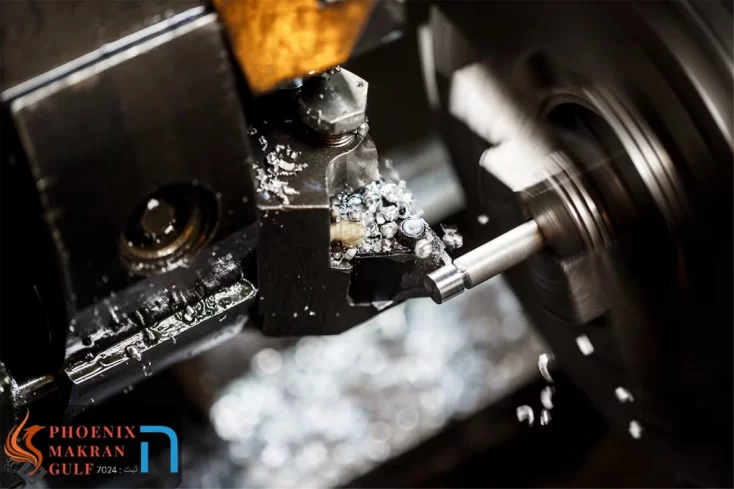

Commercial machines for chipping (shredding)

To produce wood chips, you need a wood chipper that is powerful enough to meet your needs.

No one wants to buy high-priced wood chips that also include other unnecessary wood parts like sawdust. To sort the wood chips, it is necessary to purchase a screening system that separates the chips from sawdust and extra pieces.

Find used or new wood chippers, wood chip screeners, as well as wood chip conveyor systems all in one place – Phoenix Makran Gulf. It is a team of experienced experts in the field of production, installation, dismantling and renovation of woodworking equipment.