What is an electric motor?

An electric motor is an electric machine, which converts electrical energy into mechanical energy. It works by using the interaction between magnetic field and electric current. Electric motors are used in a wide variety of applications, from powering small electric cutting devices to large industrial machinery.

When it comes to the productivity of industrial machines, the electric motor has played a major role. As a result, it is responsible for important standards that are now embraced throughout the industry.

An industrial electric motor is an electric machine that converts energy into motion. Most electric motors work through the interaction between the motor’s magnetic field and the electric current in the winding to create a force in the form of torque applied to the motor shaft.

Industrial electric motors are used for various purposes. Industrial electric motors are used in applications such as agriculture, marine, mining, oil and gas, food and beverage production, data centers, healthcare, primary and standby power, large industrial machinery, as well as general industrial equipment. Industrial engines also excel in hazardous areas.

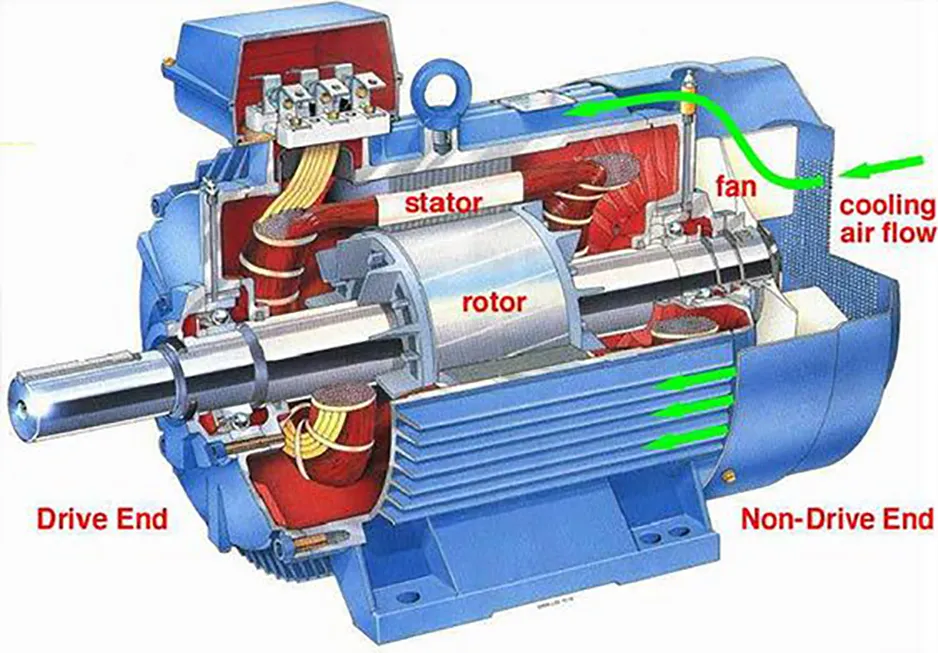

What are the components of an electric motor or an electric motor?

The two mechanical components of electric motors are the stator, which is fixed, and the rotor, which moves. It also has two electrical components, a set of magnets and an armature, one of which is connected to the stator and the other to the rotor, and together they create a magnetic circuit.

Field magnets produce a magnetic field that passes through the coil. These may be permanent magnets or electromagnets. The field magnet is generally on the stator and the winding on the rotor, but in other types of motors these are reversed.

What is a stator?

The torque or power of the motor is determined by the length of the electromagnet wire in the stator as well as the voltage. As the central part of the electromagnetic circuit, the stator core has thin metal sheets to reduce energy consumption. The stator can have permanent magnets or coils.

Types of electric motors

Electric motors can be powered by direct current (DC) sources such as batteries or alternating current (AC) sources such as the power grid, inverters or electric generators.

Industrial electric motors can be classified based on the type of power source, internal structure, application and type of motion output.

Below we briefly explain the types of electric motors along with their applications:

DC series electric motor

DC series electric motor, the operation of this motor mainly depends on the electromagnetic principle. Whenever a magnetic field is approximately formed, a current-carrying conductor aligns with an external magnetic field, and then a rotational motion is created.

See also:

Investigating the quality of the industrial workshop and its factors

DC shunt motor

In electric motors, series circuits and parallel circuits are commonly known as series and shunt. Therefore, in DC motors, the connection of the field coil and also the armature can be done in parallel, which is known as DC shunt motor. The main difference between series DC motor and also DC shunt motor mainly includes construction specifications, performance and speed. This motor offers features such as easy reverse control, speed regulation and low starting torque. Therefore, this motor can be used for belt drive applications in automotive as well as industrial applications.

Cumulative compound DC motor

A cumulative compound motor has high starting torque and variable speed.

Slip ring induction motor

An induction motor is an electrical device that converts electrical energy into mechanical energy. Due to its self-starting feature, it is mostly used for industrial applications. The slip ring induction motor is one of the types of 3-phase induction motors and is a type of slip ring rotor motors. Due to various advantages such as low starting current, high starting torque and improved power factor, it is used in applications that require high torque, cranes and elevators. The coils are connected to an external resistor via slip rings which help control the torque/speed of the motor.

Squirrel cage induction motor

Electric motors are simple in design, easy to use, low cost, high efficiency, low maintenance, reliable. Three-phase induction motors are one of the types and different from other types of electric motors. The main difference is that there is no electrical connection from the rotor winding to any power supply.

Squirrel cage electric motor is one of the types of induction motors. In order to create motion, it hardens electromagnetism. As the output shaft is connected to the inner part of the rotor which looks like a cage. Hence, it is called a squirrel cage. The two-sided i.e. circular caps are connected by rotor bars. These operate on the basis of EMF i.e. generated by the stator. This EMF is also manufactured with an outer casing made of multi-layer metal sheets and coils. The two main parts of any type of induction motor are the stator and the rotor. Squirrel cage is a simple method to draw the effect of electromagnetic induction.

Double squirrel cage induction motor

The rotor of a double squirrel cage motor has two independent cages in one rotor. Rods with high resistance and low reactance are placed in the outer cage and rods with low resistance and high reactance are placed in the inner cage. The outer cage has a high “reaction to resistance ratio” while the inner cage has a low “reaction to resistance ratio”.

Three-phase synchronous motor

Like any other electric motor, the 3-phase synchronous motor also consists of two main parts, the stator and the rotor. The stator has a 3-phase armature winding and receives power from a 3-phase AC power supply. The rotor is a rotating part and carries a field coil that is excited by an external DC power source.

The most important disadvantage of the synchronous motor is that it is not self-starting, so an auxiliary device must be used to start it.

Single phase synchronous electric motor

The main purpose of single-phase synchronous motors is the constant speed requirement, even though they have very low efficiency. Their use is usually limited to operations where speed is critical and torque requirements are low.

AC series single phase motor

An electric motor that works with a single-phase AC source is called an AC series motor. This motor has stator and rotor windings which are connected in series and supplied from the same AC source.

AC series electric motor may work with both single phase AC source and DC source. AC series motors are also known as modified DC series motors.

Repulsion electric motor

See also: Inclined guillotine scrap iron

Induction motor with starting capacitor

Capacitor start motors are single-phase induction motors that use a capacitor in the auxiliary winding circuit to create a greater phase difference between the current in the main and auxiliary windings. This electric motor uses a capacitor to start.

Electric motor with capacitor starter and permanent capacitor

Design and production of smelting and recycling machines

Phoenix Makran Gulf Company, is a manufacturer of shredders and recycling machines., for information and orders, refer to the link below.