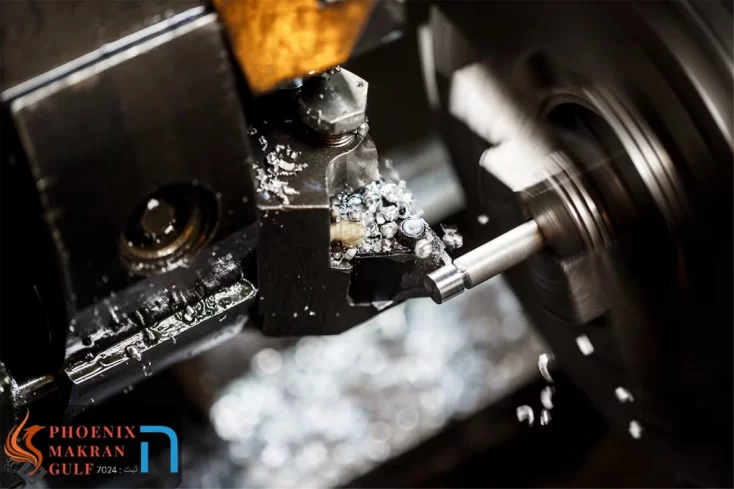

Metal crusher

Scrap metal must be processed to be effectively recycled and ready for reuse. Metal shredders are machines that are used to process all kinds of metal waste. Metal shredders are often used to reduce scrap metal to standard shapes and sizes for sorting and additional processing in scrap yards and metal recycling operations. They offer long-lasting performance thanks to their robust design. Metal shredders make it possible to shred ferrous and non-ferrous metals into new metal before sending them to steel mills for recycling. In addition, they allow companies to destroy metal materials if necessary.

Phoenix Makran Gulf Company, manufacturer of shredders, for information and orders, refer to the link below.

Advantages of using shredders

Environmental Protection:

The use of metal shredders reduces the impact of metal waste on the environment. As mentioned earlier, the shredded metal in a metal shredder can be recycled or reused. This recycled material ensures that the unused metal does not land near water sources or wet locations. The use of waste shredders eliminates the negative effects of metals on the soil, groundwater and landscape. In addition, recycled metal reduces environmental hazards such as air pollution.

It is affordable:

The use of metal shredders is completely economical. These machines provide a low-cost option for hauling scrap. In addition, a metal shredder does not produce any chemicals.

A metal shredder facilitates the separation of damaged metal scrap. Any metal crusher usually separates each metal into ferrous and non-ferrous elements. Metal recycling is made easier by using a metal shredder. In addition, a metal shredder ensures that the metal is safer after processing.

Recycle:

Using metal shredders to facilitate metal recycling is one of its main goals. Those working in the recycling sector invest in metal shredding equipment as an essential part of their operations. When scraps are crushed inside metal shredders, new, pure metal is created that can be used in a variety of ways. The resulting tiny metal parts can be melted down to become molten metal. This molten material can be used to create new and usable parts. As a result, users will not need to buy new metal to produce additional products.

The operation of the metal shredder is simple because the metal is crushed and the volume of the material is reduced. In addition, a metal shredder usually takes up little space for a facility and rarely requires additional personnel to manage. Due to their small size, shipping costs are minimal.

One of the main advantages of the metal shredder is to remove contaminants from the metal. Therefore, this process increases the purity and value of the metal.

Most electronic devices and their components are made of precious metals such as silver, gold and platinum. Low-speed metal shredders can separate and recover these metals in the pre-processing stage of shredding.

Due to the pressure on their financial resources, project developers are looking for ways to save costs while producing livable and quality structures. Shredders produce shredded metal that can be turned into cheaper products, landscaping materials, and insulation for buildings. Additionally, once the waste is turned into scrap, a recycling company’s costs are significantly reduced if they are also hired to collect the waste from a construction project. Therefore, project developers include a permanent on-site crusher in their proposals for most projects.

Phoenix Makran Gulf Company, manufacturer of shredders, for information and orders, refer to the link below.

See the article “What is a metal shredder” in the link below.

Also read the article below

I find it interesting that using shredders to facilitate scrap metal recycling services would help in creating pure materials which can be reused in many different ways. I should look for a facility with that kind of equipment so that I can be sure that they are actually helping the environment reduce the waste going into landfill. And that can only happen if the items are reused for other purposes no matter what kind of project they are used for.

When it comes to recycling and reuse of metals, no industry could function without the indispensable metal shredder. This high-powered machinery is vital in the fields of garbage collection, scrap metal processing, and material recycling. Steel, aluminum, copper, and other metals can all be shredded with the right equipment. Large metal artifacts are dismantled using blades and hammers so that they can be more easily recycled.

thanks for info

It’s great that you explained that metal shredders can be used to facilitate metal recycling. My friend wants to get their metal recycled. I should advise him to hire an expert in metal recycling to ensure quality work.