Investigating the separation of precious metals

A wide variety of different types of electronics and other electronic objects contain at least one type of precious metal. In many cases, small amounts of these metals are used inside objects. In order to recover those metals after the object is worn or crushed, you need to know exactly how to remove the metal. To separate metallic solids from objects or materials containing metal in small amounts, the smelting process is used, a process that separates different types of metals from each other.

Over the past years, the metal trade has become accustomed to the fact that the price of precious metals is increasing on a daily basis, and many members of the trade have made substantial incomes from buying and selling scrap. In recent years, several tons of fine gold have been returned to the global gold supply chain. But what happens to waste between the customer who sells it and its recycling into the supply chain?

Some examples of separation of precious metals

- Recycling and separation of precious metals from electronic waste

- Recycling and separation of precious metals from municipal solid waste

- Effective recovery and separation of valuable metals from lead sludge

- Separation of heavy metals from soil

- and similar cases

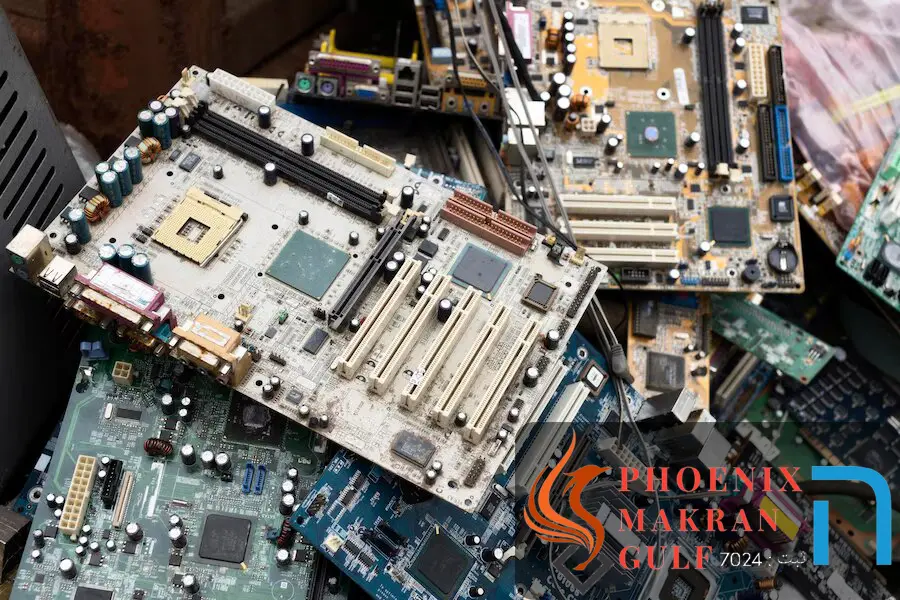

Separation of precious metals from electronic waste

Separation and recovery of metals is critical to successful e-waste recycling and helping the environment.

Metal recovery from electronic waste such as electronic boards with a wide range of different metal sizes is inherently challenging. A typical e-waste recycling process involves several metal separation steps. The separation steps with the waste melting method include shredding the electronic waste and turning it into smaller pieces with a waste shredder or guillotine, separating with a magnet, melting and then re-separating.

Recycling and separation of precious metals from municipal solid waste

Bottom ash from municipal solid waste incineration (MSWI) contains economically significant amounts of silver and gold. In order to establish accurate statistics of gold particles, for the bottom ash sample of heavy non-ferrous waste produced from 15 tons of wet processed ash containing approximately 10 ppm (intended weight per million total units) silver and 0.4 ppm gold, which is obtained in the form of particles. Available in all sizes below 20mm. Precious metal value in particles smaller than 2 mm appears to derive mainly from waste electrical and electronic equipment (WEEE), while precious metal particles larger than jewelry represent the bulk of the economic value.

Economic analysis shows that the separation of precious metals from ash may be viable at the current high prices of non-ferrous waste. In order to recover the precious metals, the bottom ash must first be classified into different size fractions. Then, heavy non-ferrous metals (HNF) should be separated by physical separation (eddy current separation, density separation, etc.). Finally, gold can be separated from other metals (copper, zinc). Concentrates enriched with gold can be sold to precious metals smelters and copper and zinc to rice or copper smelters.

Effective recovery and separation of valuable metals from lead sludge

High level lead anodic sludge (LAS) contains valuable silver and gold as well as high levels of harmful elements, mainly As, Sb and Te. The traditional method of pyrometallurgy, which is a complex Pb and Sb extraction process, is used to recover precious metals.

Therefore, vacuum distillation has been investigated to recover silver and gold from LAS. Research shows that rapid and effective recovery of valuable metals from LAS is feasible. The remaining material can be returned to the vacuum smelting process to refine the gold and silver. In this vacuum distillation process, no gas or waste water is discharged, and as a result, valuable metals are recycled sustainably and cleanly.

Separation of heavy metals from soil

In this method, by laboratory examination of the soil sample, if there is an acceptable amount of precious metals in the scale of the soil used. By using smelting and recycling furnaces and the combined smelting process, an acceptable amount of precious metals can be obtained at the same time.

Of course, in all the methods of separating precious metals, it is not possible to specify a fixed amount to obtain valuable metals.

The method of separating precious metals through the melting process

Shredding waste

Before starting the separation process, the waste must be crushed and turned into smaller pieces for better separation and better melting of the materials. A shredder machine is used to shred the waste.

waste melting

A tilting furnace is used to melt waste. Before using the furnace, the necessary protective equipment must be used. When the furnace is ready, scraps are placed inside the furnace and the furnace starts to heat up. The temperature inside the furnace should be checked and the minimum temperature inside the furnace should be heated to 1200 degrees Celsius (or about 2192 degrees Fahrenheit).

Waste melting liquid

After a certain period of time, a molten liquid is obtained, which usually requires adding silica and sodium borate chemicals to the molten liquid for better separation.

Dissolution of metals

Slag preparation is not done at high speed. Rather, it takes about an hour and a half for the metals to dissolve. If the metals are not completely dissolved during this time, the furnace temperature should be increased to about 1400 degrees Celsius (or about 2552 degrees Fahrenheit).

Separation of gold metal and other metals

Heating the slag is continued until the molten gold begins to dissolve from the rest of the slag. This occurs due to the melting point and density of gold compared to the different melting points and densities of the other metal components of the slag. Gold must be poured into the melting pot.

After this, the gold and metals can be removed from the cooled melting pot and the slag can also be separated. At this stage, it is common to refine the gold through a separate refining process to ensure a high level of purity. For more information on separation methods, consult an expert or experienced in the field of waste smelting.

Phoenix Makran Gulf Company, is a manufacturer of shredders and recycling machines., for information and orders, refer to the link below.

I will right away grab your rss feed as I can’t find your e-mail subscription link or newsletter service. Do you’ve any? Kindly let me know in order that I could subscribe. Thanks.

I like this web site because so much useful material on here : D.