What is coupling?

shaft Coupling is a mechanical device that connects shafts in machines to transmit power and movement. It is usually a temporary connection (but in some cases it can be permanent) and can be removed for service or replacement. A coupling may be rigid or flexible.

Simply put, couplings are mechanical devices used to transmit power/torque from one shaft to another. A coupling can also be considered as a device used to connect two shafts together at their ends so that power can be transmitted. However, the primary purpose of couplings is to connect two pieces of rotating equipment, allowing for some degree of misalignment or end movement, or both.

In a general context, a coupling is a mechanical device that serves to connect the ends of adjacent parts or objects. Typically, they do not allow the shafts to separate during operation, but torque-limiting couplings are also available. These couplings can slip or separate if the torque limit is exceeded.

Of course, couplings can only transmit torque over short distances, for longer distances, chain drives and belts are better alternatives.

See also: What is an industrial electric motor? Types of models and applications

What is shaft coupling?

A shaft coupling is a mechanical component that connects two rotating shafts such as a drive shaft in order to transmit power. It is used in engines, pumps, generators, compressors and shredders.

A shaft coupling is a piece of mechanical element that connects two shafts to each other in order to accurately transfer power from the drive side to the other drive side by absorbing the installation error (misalignment) of the two shafts.

Coupling in the machine industry is defined as “the part that connects two shafts” and is generally called “coupling”, “shaft coupling” or “joint”.

Using a coupling, power can be transferred even between axes with different diameters.

Shaft coupling is used to transfer power and torque between two rotating shafts such as motors and pumps, compressors and generators. Shaft couplings are available in small type mainly for factory automation and large casting type used for power transmission such as wind machines and hydraulic power.

As a result, this coupling flexibility can reduce uneven bearing wear, equipment vibration, and other mechanical problems caused by misalignment.

Flexible shaft couplings can avoid these problems by transmitting torque while compensating for parallel, angular, and axial misalignment between drive components. When properly installed, flexible shaft couplings can reduce vibration, minimize noise and protect drive shaft components.

Coupling applications

Shaft coupling is used in almost all industrial machines for several purposes. The main task is to transfer power from one end to the other.

The main applications of coupling include:

- To transfer power from the drive shaft to the drive shaft.

- Couplings connect or couple two separately manufactured components, the output motor shaft and the generator.

- By using flexible couplings, it reduces the transfer of shock loads from one shaft to another.

- Couplings are also used to create more flexibility during power transmission if space is limited.

- Used to introduce overload protection.

Types of couplings

Beam Coupling

A beam coupling, also known as a helical coupling, is a flexible coupling for transmitting torque between two shafts while allowing for angular misalignment, parallel offset, and even axial movement of one shaft relative to the other.

Like all couplings, the goal of Beam Coupling is to transfer torque between two shafts, but unlike rigid coupling, Beam Coupling can accommodate angular misalignment, parallel offset, and even axial movement of one shaft relative to the other.

Sleeve Or Muff Coupling

Sleeve Or Muff Coupling is a basic type of coupling. It consists of a tube whose bore is completed to the required tolerance based on the size of the shaft. Based on the use of the coupling, a key is created in the hole to transmit the torque using the key. Two holes are provided to lock the coupling in position.

Sleeve Coupling is the simplest type of shaft coupling and is used to transfer power to medium torque. This tube consists of a thick and hollow cylindrical tube called sleeve or muff, whose inner diameter is the same as the shaft. The sleeve transmits the torque across the shafts.

Split Muff Coupling

Split muff coupling is also called push coupling or clamp coupling. This is a rigid type of coupling. In this coupling, the shell is made of two halves. Muff halves are made of cast iron. The two grass halves are connected using steel studs or bolts.

The number of screws can be four or eight. They are always a multiple of four. The screws are placed in the depressions formed in the shell halves.

The advantage of this coupling is that it is not necessary to change the position of the axes to assemble or disassemble the coupling. This coupling may be used for heavy and medium speeds.

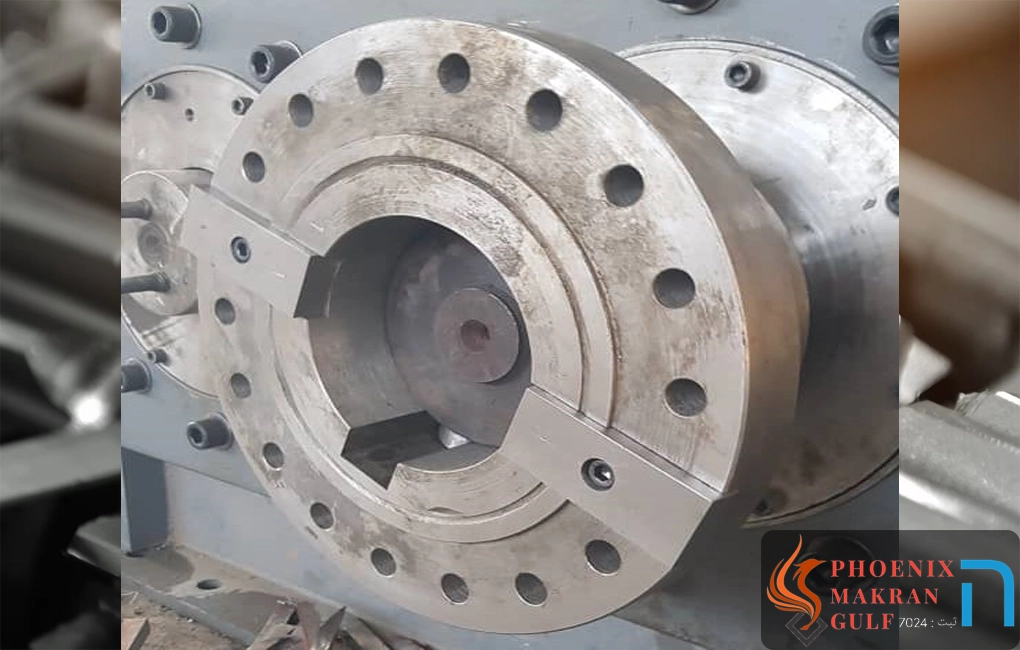

Flange Coupling

Flange coupling is a driving coupling between rotating shafts, which consists of flanges, one of which is fixed at the end of each shaft, and the two flanges are connected with a ring of screws to complete the drive.

This type of coupling is intended to bring the two ends of the pipe together in a smooth and sealed manner. This two-piece coupling unit consists of a keyed receiver side for connecting a flanged end, so it may be connected to the opposite pipe end, which also has a flanged end.

Each flange has a male or female coupler opening so that when the two ends are brought together, they align without resistance. This method of male or female coupling also creates a stable connection that resists displacement and holds the flanged coupling firmly in place.

Disc Coupling

A disc coupling, by definition, transmits torque from a drive to a screw or drive shaft tangentially on a common screw circle. The torque between the screws is transmitted through a series of thin, stainless steel discs assembled in a package. Misalignment is accomplished by deformation of the material between the screws.

This type of coupling is a high performance motion control coupling designed as a torque transmitting element (connecting two shafts together) while also accommodating shaft misalignment. Designed to be flexible while remaining torsionally strong under high torque loads. Typically, disc couplings can handle speeds up to 10,000 rpm.

Bushed Coupling

Bosch couplings are primarily used as flexible couplings in applications where reliable coupling transmission is required under severe operating conditions. A bushing coupling consists of two balls that can be made of different materials and is mounted with pins where rubber bushings are attached.

These types of couplings are flexible couplings that are reliable and therefore widely used in lifting applications.

See also:

Investigating the quality of the industrial workshop and its factors

Diaphragm Coupling

Diaphragm coupling consists of one or more metal membranes that are attached to the outer diameter of the driving flange and transmits the torque radially through the diaphragm to the attachment of the inner diameter. Another type of metallic membrane coupling is disc coupling.

Diaphragm couplings use a series of plates or diaphragms for flexibility. It transmits torque from the outer diameter of a flexible plate to the inner diameter, across the pulley or spacer piece, and then from the inner to the outer diameter.

Grid Coupling

Grid Coupling, like disc and gear couplings, are designed with high torque density applications in mind. It usually consists of two shaft hubs, a split horizontal cover kit and a spiral mesh.

Grid Couplings is a proven, versatile technology with interchangeable components readily available from several major coupling manufacturers.

These couplings have high power density (they transmit a high amount of torque relative to their size) and are relatively simple to install. They also have good resistance to environmental conditions and are suitable for inch and metric holes.

Roller Chain Coupling

The roller chain coupling is a mechanical device that consists of a double strand roller chain and two modified gears. Despite its small size, this design is simple and very effective, and consists of a strong chain and hard toothed gears that allow high torque transmission.

These types of couplings are very simple but provide a compact and flexible coupling that is suitable for a wide range of applications.

Due to the design, the torque is distributed across the roller chain and gear teeth, so when moving, the torque is evenly distributed throughout the coupler.

Gear Coupling

Gear couplings are designed to transmit torque between two shafts that are not linear. They usually consist of two flexible joints, one to each fixed shaft, connected by a third spindle or shaft.

A gear coupling connects the drive motor to the gearbox in hoist mechanisms, but can also connect the gearbox directly to smaller drums using a half flange.

Tyre Couplings

Tire couplings are shaft couplings with a flexible body that compensates for misalignment and protects other transmission system components.

Tyre couplings are very flexible and free from torsional reaction. These couplings are especially suitable for coupling machines with a very non-uniform torque pattern.

The coupling transmits torque by frictional engagement.

This coupling can be used at different temperatures according to the type of tire.

Jaw Coupling

A jaw coupling is a general purpose power transmission coupling that can also be used in motion control applications. This coupling is designed to transmit torque (by connecting two shafts) while controlling system vibrations and accommodating misalignment. which protects other parts from damage.

It transmits torque and controls vibration.

Oldham Coupling

The Oldham coupling is a three-piece assembly. which consists of two light or corrosion-resistant aluminum stainless steel hubs and a central disc.

Oldham coupling is a form of flexible coupling designed for applications that must be free of backlash. They are also increasingly used as an alternative to direct couplings. Oldham coupling consists of three discs.

Two of the disks are attached to either side of the drive, while the third is sandwiched between them with a tongue-and-groove design.

The tongue and groove on one side is perpendicular to the tongue and groove on the other side. Springs are often used to reduce coupling reaction.

In operation, the central disc slides on the tabs or lugs of each ball (which are spaced 90 degrees apart) to transmit torque. While couplings accommodate a small amount of angular and axial misalignment, they are particularly useful in applications with parallel misalignment.

Oldham couplings have several other advantages, including compact size and the potential for electrical isolation through a plastic center disc. Couplings may also act as a type of fuse for the device.

Universal Coupling

universal coupling is used to connect two shafts whose axes intersect at a small angle. The bending of two shafts may be constant, but in practice, it changes as momentum is transferred from one shaft to the other.

The main application of universal coupling or hook is found in the transmission from the gearbox to the differential or the rear axle of the car.

Bellows Couplings

Bellows couplings are a form of flexible coupling with twin mating heads, called hubs, that cap over a precision engineered corrugated tube that serves as the coupling body.

These couplings are known for their exceptional torsional strength for precise transmission of speed, angular position and torque.

are usually made of a stainless steel tube.

The main work of coupling

The operation of a coupling device is easy to understand. It is used to connect two shafts with the same or different diameters. The engine transmits power from the drive side and the coupling is located on the drive side. The coupling does not transfer the heat of the motor etc. to the actuator. Flexible coupling can be divided into two groups. Metal and Elastomer Metal types use freedom parts that slide over each other.

On the other hand, elastomeric types are also flexible and stable.

In this article, we examined the concept of coupling along with its applications and types, we hope that it has been used by you.

Design and production of smelting and recycling machines

Phoenix Makran Gulf Company, is a manufacturer of shredders and recycling machines., for information and orders, refer to the link below.