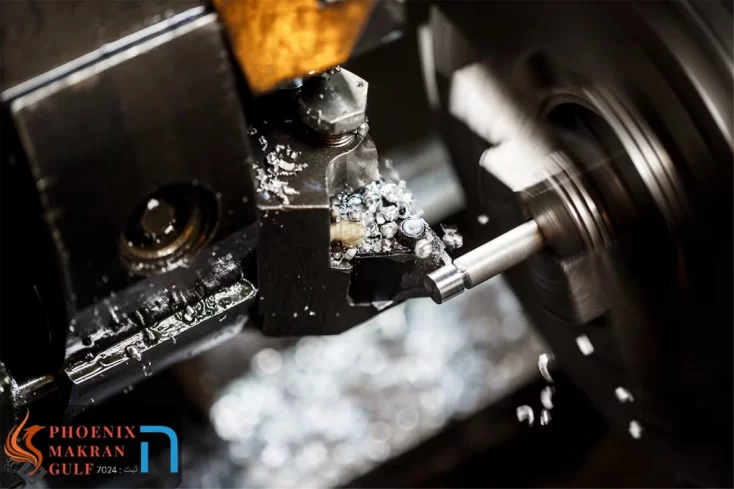

What is a computer numerical control device or CNC?

In today’s world, the use of CNC machine has grown tremendously due to its many and practical advantages over manual work and the use of human power, and has caused it to be used in all kinds of industries. In this article, we want to mention this technology and its device.

Because limited people may be familiar with this technology, while they may see decorative objects or other objects around them that they did not know how and with what technology and device they are made.

CNC machines have the ability to perform different operations such as cutting, turning, drilling, etc., which you will get to know about its other features below.

Introduction:

The first generation of these devices were NCs, which means they moved without computer control. The device has received commands according to a special logic and understood them in a linear or copy-like manner. For example, using punched cards.

For example, in the lathe machine, for the advance order, the support part of the machine is moved forward by the rotating handle. In NC machines, this work was done by a series of punched commands on the punch bar in today’s CNC machine. This is done by a code.

A CNC machine is a simple manual machine that can be controlled through codes and mathematical logic. In this machine, the presence of the user (operator) to work with the machine is limited to standing behind the controller and writing motion programs only. It is scheduled for one time.

, then the device automatically repeats this action as many times as we want, of course, without the presence of the user. The body of this device is almost similar to manual devices. Other CNCs, like metal CNCs, have the same hardware body as hand mills, as well as CNC lathes and stone CNCs.

Types of CNC machines

CNC machines are very diverse. The most famous of them are CNC laser machines and CNC milling machines.

CNC laser devices are divided into two categories: metal laser devices and non-metal laser devices.

Metal laser device:

The metal laser device is used for things such as engraving, cutting, turning, welding, etc. on different metals.

Laser metal cutting or laser metal cutting is one of the most advanced cutting techniques. Among the advantages of laser cutting are speed, accuracy and no need for post-cutting processing operations.

Non-metal laser device:

Using a non-metal laser device, you can perform all kinds of cutting and engraving operations on various materials such as plastic, plexiglass, wood, glass, fabric, etc.

Non-metal laser CNC machines can be used to make wall clocks, boxes, photo frames, series of desktop office equipment, small and large (entertainment) puzzles, making replicas, automatic advertising engraving, recognition plaques, making signboards, engraving. He pointed out on fabric, bags and shoes, leather and….

cnc milling

The third type of CNC machine is a milling machine, in which a milling tip is used instead of a laser. The CNC milling machine is suitable for cutting and engraving all kinds of stone, wood and metals, and its advantage over the CNC laser machine is the depth of cutting and engraving.

Other types of cnc machines

There are other types of CNC machines, plasma cutting machine, air cutting machine, waterjet machine or waterjet cutting machine or water cutting machine, etc., which have many applications in various industries.

Plasma cutting machine:

Plasma cutting is a cutting process with an electric arc and it can be done on any type of conductive metal, mild steel, aluminum, stainless steel (stainless steel) and… and in terms of price, quality and facilities, it is between air gas and laser.

This cutting machines have the ability to cut all kinds of metal sheets and slabs and are used in various industries such as machine-making, mold-making, steel-making, slab-making, chandelier-making, etc.

Air cutting device:

In these devices, gas fuel with oxygen is used to weld and cut metals.

The air cutting machine has its own users due to its simple and cost-effective use, and it may not be easily replaced by another machine, but due to the slow cutting speed and low accuracy in some industries, instead of the air cutting machine, the machine is used. They use plasma or laser cutting. This machine is used to cut flat sheets and thicker sheets.

Waterjet cutting machine:

A water jet is also a device for cutting, which works with a very high pressure stream of water. It may sound strange, but if the water velocity is increased enough, it can even cut metals and rocks.

The cutting of waterjet devices is by water that is directed from a very narrow nozzle made of precious stones with very high pressure and directly on the target.

One of the advantages of water jet devices is that unlike industrial saws, they never stop working due to heating, besides, these cutting devices are odorless and dust-free.

It is used in the manufacture of industrial parts, aerospace industries, construction industries, glass industry, wood industry, component manufacturing and automotive industry, textile industry, electrical and electronics industry, and food industry.

Parameters affecting the price of cnc machines

The price of CNC machines is very different according to the variety of its models. In general, CNC machines are priced based on the following parameters.

- Type and quality of parts

- Spindle power: the more powerful the spindle of a milling machine is, the faster it can perform engraving or cutting operations and the higher the price will be.

- The number of axes of the machine: the more the number of axes, the higher the price of the machine.

- Motion control mechanism: Some CNC machines have a motion control mechanism.

- Material of the structure: The thickness and material used in the profiles and sheets used in the CNC structure are effective in the strength of the device and its price.

- Accessories and accessories of the device:

CNC milling machines have different prices depending on what accessories they are equipped with.

Some types of accessories of CNC machines are:

- Automatic lubrication equipment

- Chiller for spindle cooling

- Dust collector in special devices for wood

- Manual control to control the movement of the device by hand.

Applications of CNC machine in building

One of the areas where CNC machines are used is construction.

Of course, there is no need for this device as long as the construction and so-called hardening process is done; But this device is widely used in building carpentry.

The first part that is used in the construction of this industrial device is the facade of the building. It doesn’t matter if stone or wood is used in the facade of the building or the interior of the albi, etc., the CNC machine can be a good option for cutting them accurately.

CNC wood or stone cutting machine, both depending on the type of facade of the building, will play a significant role in increasing the facade quality.

In addition, if the walls inside the apartment units are to be hammered and special designs are to be carved on it, the CNC machine can be a suitable option for this work so that the work is done as accurately and cleanly as possible.

Decorations

CNC machine is widely used in the decoration market. Many of the items you see in the market are produced using this machine. These decorations have different branches. For example, many inlays that were created by hand and with great effort are now made at a cheaper price using a CNC machine. Although handmade art is something else, the items produced by this machine are also good, clean and without are defects.

CNC machines are also used to make decorative windows or patterned doors that play the role of decorations in homes or commercial units. Of course, the machine is also used to make decorative items such as stone and wooden frames or stone vases, which in some cases cannot be made by hand.

Conclusion:

The purpose of writing this article was to familiarize with CNC, its uses and features.

And as a result, after reading this article and getting to know about this technology and its features, if we see something around us that is made of technology, we will no longer have questions about how this object is made and have a relatively sufficient knowledge of the type of device. We will have the type of work of the device and even the price of that object.

Phoenix Makran Gulf Company is a manufacturer of various types of industrial and recycling machines, for more information and order, please refer to the link below.