Rubber powder: best uses

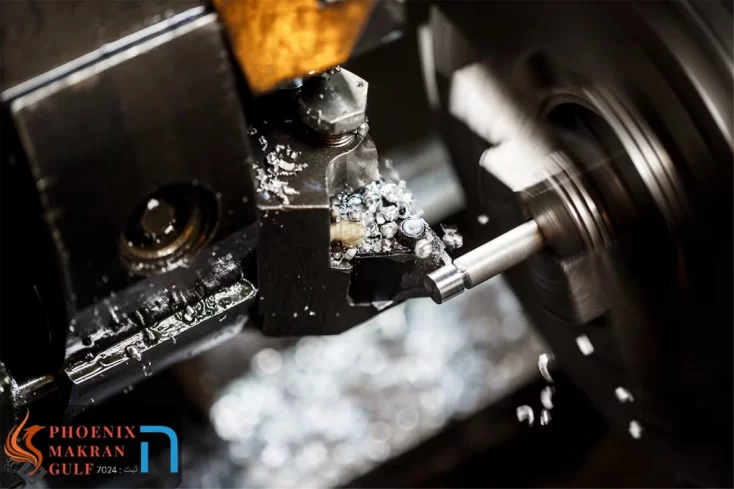

Rubber powder is the end result of physical tire recycling. At this stage, the crumb rubber is reduced to a clean powder and almost all steel and fibers are removed. Rubber powder has many secondary applications from injection molding products, coatings, fuel production and various asphalt usage.

What is rubber powder?

Before production starts, the machines are adjusted according to the type of material one wants to obtain, e.g. The rubber granule is mostly sieved based on the size instead of molding, the rubber powder is filled in the desired tank and containers depending on the choice of the customers.

Rubber powder is the best product after recycling used tires. The name “powder” clearly indicates its size, which is between 0.1 and 1 mm. It is usually completely clean of any iron and alloy impurities. This is very important for creating new objects.

Uses

The rubber dust obtained from the recycling of used tires has various uses, which are most important in the production of industrial products. Major tire manufacturers use it in new tire compounds. Rubber powder is also used in making insulating boards, sealing and anti-vibration panels. The final use is mixed with bitumen to obtain rubber asphalt.

See also: Converting rubber to diesel – a profitable business

Rubber powder markets:

- usage of molded plastic

- Additive rubber, sealant and paint

- Thermoplastic applications of modified asphalt

- Geomembranes

- Other extruded products and rubber compounds

Benefits of rubber powder:

- stress absorbing properties for asphalt application

- Performance and durability

- It is incorporated into several polymers and products

- Removes tires from landfills and the environment

Phoenix Makran Gulf Company manufactures all kinds of shredders tires, for more information and orders, refer to the link below.