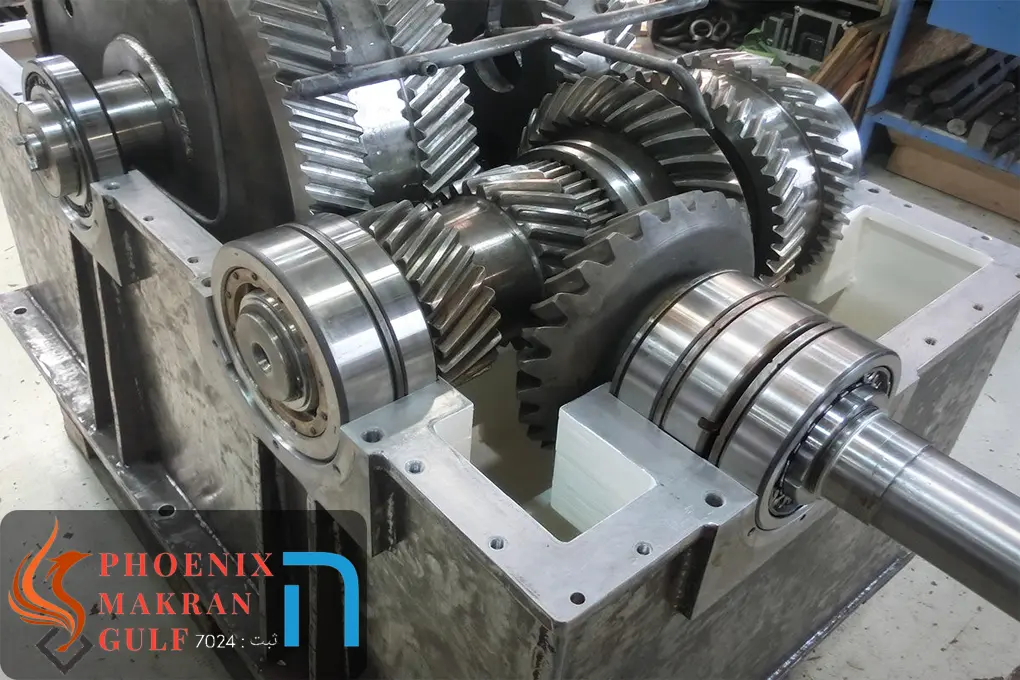

What is an industrial gearbox?

The industrial gearbox is a closed system that transfers mechanical energy to the output device. It changes speed, torque and other characteristics to provide energy in the required form. Gearboxes are used in different cars for different purposes.

industrial gearbox is a system in which mechanical energy is transferred from one device to another and is used to increase torque and decrease speed.

They are widely used in the industry to facilitate mechanical performance and use energy in a desirable and required manner.

Related articles:

What is an industrial electric motor? Types of models and applications

What is shaft coupling? Types and applications

Gearbox in industry

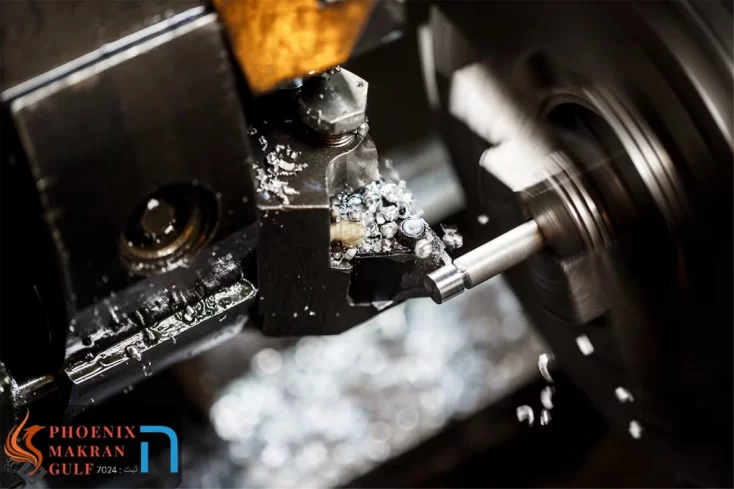

Gearboxes are used in various industries because they perform many functions. The simple definition of an industrial gearbox is a set of gears, which increase either torque or speed, but usually not both. These machines can be found on conveyor belts and in cooling systems, among many other parts. In fact, many industries use a combination of gearboxes depending on the performance required for each job. Some of the largest sectors where these machines are used include the recycling, paper, cement, feed and steel industries.

Now industrial gearboxes with high power, high speed and low noise. They have become very important transmission equipment in various industries. Such as wind turbines, crane hosting, construction. The industrial gearbox has an important place for the industrial production process.

Industrial Machinery

Industrial machines are usually used for large-scale manufacturing and application industries. Likewise, industrial equipment is used in a large-scale commercial environment for heavy industry.

For example, to build a skyscraper, you need an industrial crane and other equipment. Or for oil drilling, huge industrial oil rigs are required. To provide wind power, you need industrial wind turbines, and for the recycling and smelting industry, you need powerful industrial machines.

An important part in industrial machines is the gearbox, without this functional machine, power transmission does not take place properly.

In general, when we refer to industrial machinery, it means large and durable equipment. One of the most important factors in the discussion of industrial gearboxes is resistance, strength and durability.

In the future, more industrial machines will be used. But as long as the world keeps building new things, the demand for industrial equipment will continue to grow. Even if some tasks are automated, the machines and devices that do the work still need industrial equipment such as gearboxes and other essentials to do the work.

Types of gearboxes

Below are the types of gearboxes in terms of efficiency and use in the industry along with additional explanations:

Helical gearbox

In helical gearboxes, helical gears are power transmission components that are mainly used to reduce speed and increase torque between rotating axes. Basically, they can be divided into two groups, those that transmit power between parallel shafts and those that transmit power between non-parallel shafts. which is usually known as axial gears.

Helical gearboxes are unique in that they are at a fixed angle. When moving, it enables more gears to interact in the same direction. It provides constant communication for a specified period of time.

The best way to understand a helical gearbox is to imagine many identical gears cut out of paper and glued together so that each successive layer moves slightly ahead of the one before it. For such a system to work, the mating gear must move its layers in opposite directions. Therefore, helical gears coupled on parallel shafts are necessarily right-handed and left-handed.

Worm gears are important because they provide a uniform, silent, and efficient transmission of motion and power between two parallel shafts.

This equipment is used for a wide range of industrial applications, but is typically used in heavy duty operations. Worm gearboxes are popular in the manufacture of plastics, cement, rubber and other heavy industrial machinery. It is useful in shredders, extruders, coolers and conveyor belts, all of which are low-power applications.

Coaxial helical inline

Coaxial in the case of gearboxes in a simple definition means that the input and output shafts of the gearbox are located on the same axis of rotation.

The input and output shafts are usually connected through two pairs of gears, and thanks to a suitable arrangement, they can be located on the same axis of rotation.

Coaxial helical gearbox is ideal for heavy duty applications. Coaxial spiral lines are considered for their quality and efficiency. which are produced with a high degree of specification that allows you to maximize the load and transfer ratio.

See also: Separation of precious metals

Bevel helical gearbox

The important feature of this type of gearbox is the set of curved teeth that are located on the conical surface near the edge of the unit. Bevel-helical gearboxes are used to create rotational movements between non-parallel shafts. These are commonly used in mines, in the mining industry and on conveyors.

Bevel helical gears are an essential component for applications where the direction of force must be changed and a high degree of torque or power output is required.

Skew bevel helical gearbox

This very new and innovative gearbox relies on helical gears with diagonal axes and combines economical cost (typically helical gearboxes) and high efficiency (typically bevel helical gearboxes) in a single concept.

Diagonal helical gearbox is notable for its robust and integrated structure, which makes it suitable for heavy loads and other applications. These industrial gearboxes have special mechanical advantages when installed on the correct motor shaft output. They are highly adjustable based on the number of teeth and gears.

Worm reduction gearboxes

Helical gear reducer is one of the types of reducer gearboxes, which consists of worm pinion input and output helical gear. This type of reduction gearbox is usually used to take the rated speed of the engine and produce a low speed output with a higher torque value based on the reduction ratio.

The gearbox (spiral reducer) is one of the most economical gearboxes to save space due to the small diameter of its output gear.

See also: Investigating the quality of the industrial workshop and its factors

Planetary gearbox

A planetary gearbox is a gearbox where the input shaft and the output shaft are aligned. A planetary gearbox is used to transmit the greatest torque in the most compact form (known as torque density).

The planetary gearbox is ideal for its endurance, precision and distinctive performance and is notable for its precise applications. This type of gearbox increases the life of your equipment and optimizes performance

In this article, we examined the concept of industrial gearbox along with its applications and types. Phoenix Makran Gulf Company, is a manufacturer of shredders and recycling machines., for information and orders, refer to the link below.