What does metal plating mean?

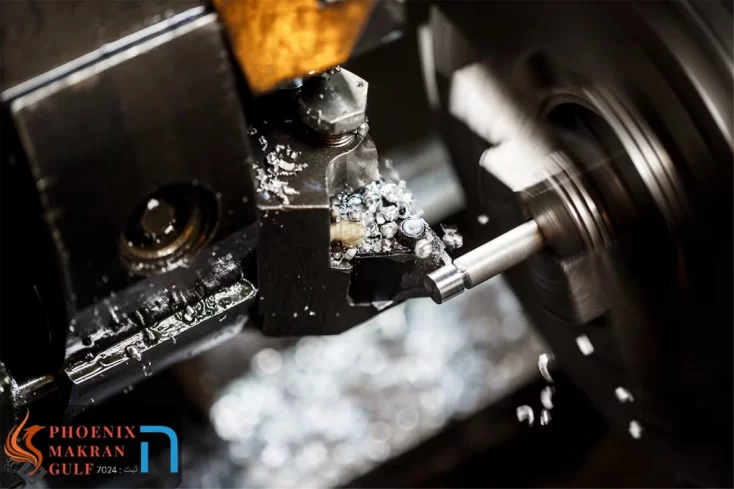

Metal plating is a thin layer of metal that is added to the exterior of a material. It is a coating process in which a metal is deposited on a conductive surface. Plating has been done for hundreds of years. It is also vital to modern technology.

The plating process is a manufacturing process in which a thin layer of metal covers a substrate. Metal plating provides many advantages to products made of metal and other materials.

In this article, you will learn why many engineers and researchers use metal plating at every stage of manufacturing.

Why is metal plating used?

Plating is the process of using electrodeposition to cover an object in a metal layer. Engineers use controlled electrolysis to transfer the desired metal coating from the anode (the part containing the metal that will be used as plating) to the cathode (the part to be plated).

Plating is used to decorate objects, prevent corrosion, improve solderability, harden, improve wearability, reduce friction, improve paint adhesion, change conductivity, improve IR reflection, radiation shielding and other purposes. Jewelry usually uses plating to give it a silver or gold finish.

Advantages of metal plating

Metal plating provides many advantages for products made of metal and other materials:

- Improved corrosion resistance

- Decorative charm

- Increase soldering ability

- Increased difficulty

- Reduce friction

- Changed direction

- Enhanced paint adhesion

- Deposition of materials

- Increase in magnetism

Metal plating materials

You can plate a single metal on an object or a combination of metals. Many manufacturers choose metal layers such as copper and nickel to maximize strength and conductivity. Materials that are commonly used in electroplating. as follows:

- brass

- cadmium

- Chrome

- copper

- gold

- iron

- nickel

- silver

- Titanium

- Zinc

Metal plating steps

Cleaning and preparing the metal surface:

- Oxide removal

- Electric polishing

- Alkaline cleaning

Metal plating (see below for details):

- electroless plating (autocatalytic)

- Plating

- Immersion plating

Additional and protective steps:

- to phosphatize

- Chromate conversion

- to anodize

Result

In this article, a brief discussion of metal plating processes was presented. For more information on products, or advice and guidance, contact.

Phoenix Makran Gulf Company is a manufacturer of various types of industrial and recycling machines, for more information and order, please refer to the link below.